English

English Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

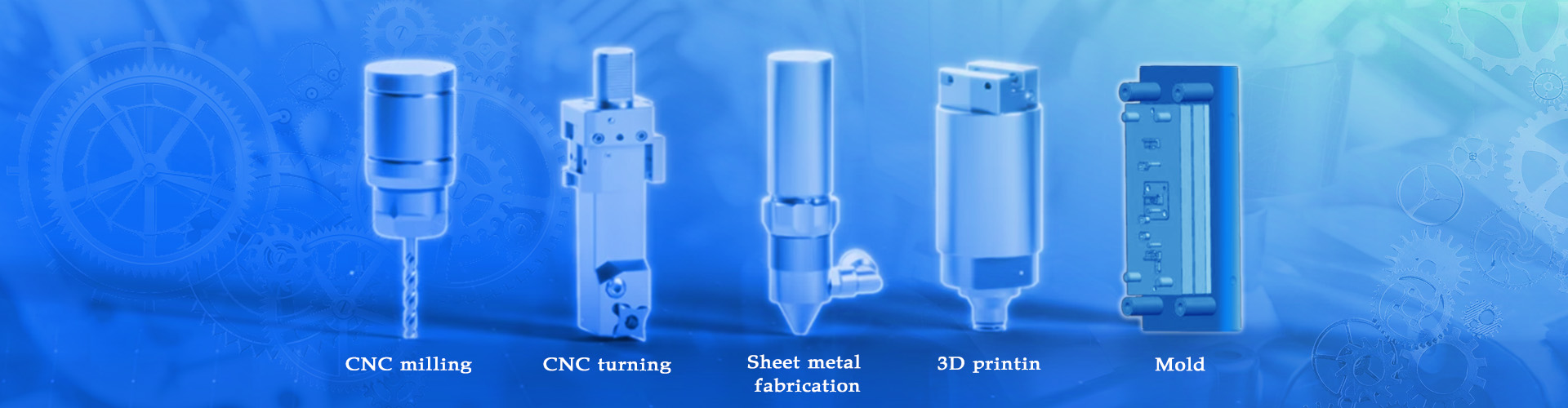

Proizvodi

- Obrada dijelova medicinske opreme

- Poluvodička precizna obrada mfg

- Obrada dijelova poljoprivrednih strojeva

- Pribor za medicinsku opremu

- Dijelovi rudarskih i naftnih strojeva

- Dijelovi preciznih strojeva građevinske opreme

- Precizna obrada dijelova automatiziranih strojeva

- Dodaci za zrakoplovne precizne dijelove

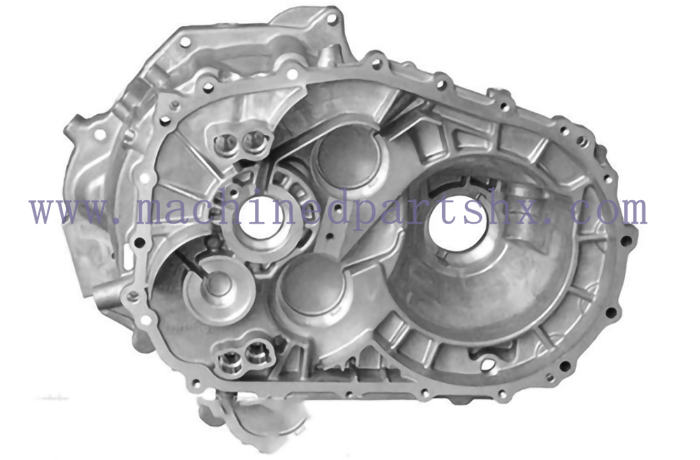

- Precizna obrada auto dijelova

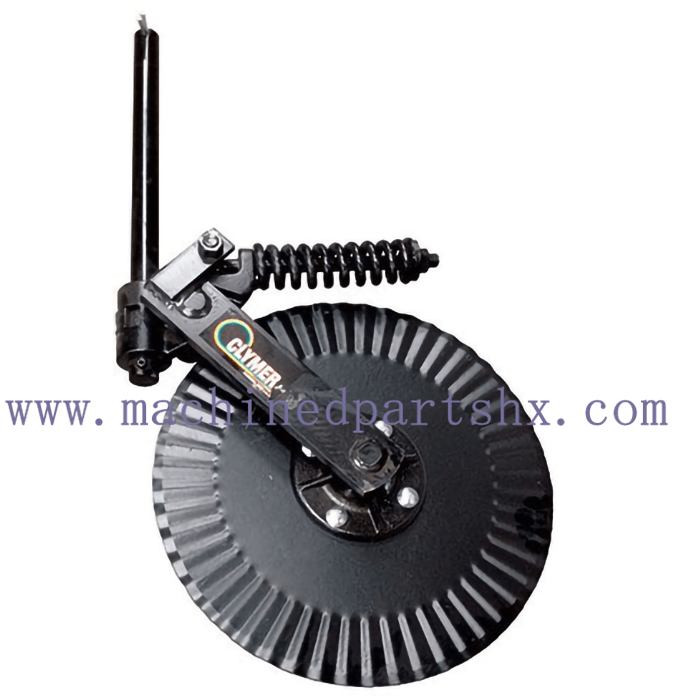

- Prilagođena mehanička remenica

- Kalup

- Precizna obrada elektroničkih proizvoda

Brass Casting Mold

Područje primjene: pogodno za umjetnost, medalje, zupčanike, ležajeve, strojarske radionice i mehaničke primjene, kao i za štancanje, umetke, čvora, komponente, kalupe, zupčanike, mjerače, alate za rezanje, odljevke, elektrode, zupčanike, zupce, ekstruzije, oblikovanje alati, kamere i prototip aplikacije za motore, pogonske sklopove i alate za primjenu kočnica i šasije od kritične sigurnosti.

Pošaljite upit

Opis proizvoda

Die Casting Mould——Brass Die Casting Mould

As a custom manufacturer of metal casting molds, HXTECH can manufacture custom manufacturers of aluminum molds used in construction, aerospace, automotive, construction, electrical, furniture, food, lightning, marine, medical and military industries.

Our die-casting molds are manufactured according to your specifications, meet your budget and warranty requirements, and use European or Chinese grade steel.

Product Details:

Product Name: Brass Die Casting Mould

Services: Provide automatic, desktop, floor and bulk molding technology; provide rapid prototyping and engineering services.

Scope of application: suitable for art, medals, gears, bearings, machinery workshops and mechanical applications as well as stamping, inserts, fixtures, components, molding, sprockets, gauges, cutting tools, castings, electrodes, gears, splines, extrusions , Forming tools, cams and prototype applications for engines, powertrains, and tools for safety-critical brake and chassis applications.

Features:

1. Including 3D solid part modeling, tool design, wire EDM, 5-axis machining and CMM inspection.

2. Including drill holes with diameters ranging from 0.12 inches to 0.12 inches, with a maximum workpiece height of 10.5 inches and weight or 682 pounds.

3. EDM functions include 5-axis functions with wire diameters ranging from 0.004 inches to 0.012 inches.

Process: Die Casting

Quality assurance:

1. Provide brass die-casting mold services for the aerospace and defense industries. Working specifications include tolerances of +/- 0.005 inches and minimum angle draft requirements of 2 to 5 degrees. It also provides extrusion, stamping, sheet metal processing, and semi-solid and injection molding services.

2. Provide a production lead time of 4 to 8 weeks. Shaping, quenching, continuous, dense, high pressure and low pressure, dipping, loose pattern, static, dumping, vacuum and carbon dioxide process castings.

3. Provide automatic, upper and lower molds, floor, permanent, plaster, shell and solid mold castings.

4. The product has the characteristics of wear resistance, acid resistance, corrosion resistance, heat and wear resistance, annealing, antistatic, enamel, plating and thin wall.

5. Applications include farm shops, auto parts dealers, repair shops and gin.

6. Functions include design, prototyping, engineering, packaging, outsourcing, blueprints, warehousing and lean manufacturing.

7. Industries served include commerce, automobiles, electronics, ships, medical care, mining, wastewater and semiconductors.

8. Comply with ANSI, ASME and ASTM standards. Comply with RoHS.

Who we are

Dongguan HX Technology CO.,LTD Start to business since 2006 which located in No.3 Dayuan Street Southwest Industry Shijie Town Dongguan City Guangdong Province PR.China.Through years of unremitting efforts and the care and support of our customers, the company has developed rapidly and vigorously. At present, HXTech is equipped with more than 50 advanced CNC processing equipment at home and abroad, such as has slow-moving wire cutting machines, optical grinding, CNC lathes, and CNC machining centers from Japan and Taiwan. There are multiple grinders, multiple precision water grinding & EDM, equipped with fully automatic punching machines and a complete set of quality control inspection equipment such as precision testing equipment (projector, 2.5-dimensional 3.0-dimensional, etc...). All of our engineers are skilled professionals with more than 10 years of experience in machining and mold industries and wire cutting. We adhere to the principle of survival by quality, development by reputation and speed, and focus on customer business needs. Provide first-class quality, 24/7 service. We will win sincere cooperation with global customers with high-precision equipment, rigorous and responsible working attitude, fast and thoughtful service and competitive prices!

Professional knowledge and quality are essential. Dongguan HX Technology CO., LTD provides highly focused attention and services for every quotation and every component.

We work differently from other services and ask questions before starting manufacturing to help our customers make better and more cost-effective parts. We are appreciated being a one-stop service provider for your parts, so we focus on making every part & every sets molds, even those parts or Molds that other companies refuse to bid on due to complexity. Most of our business comes from repeat customers. In order to achieve this goal, we strive to complete customer tasks on time and with quality on all project types.

Our major businesses are medical equipment parts processing & molds, auto parts processing&molds, semiconductor precision parts processing &molds, precision processing & molds of aerospace products, agricultural machinery & equipment parts processing, and automated machines, 5G communication product parts & other products molds &die-casting molds. We pride ourselves on taking the extra steps to ensure that the products we deliver meet and exceed our customers’ demands. We provide manufacturing expertise in the early developmental stage in an effort to reduce costs, improve product performance and reduce cycle time. Our customers have come to expect our attention to detail which often corrects overlooked issues with the many prototype projects we complete. We continue to re-invest in new technologies to improve our processes, increase our capacity and lower our costs. We strive to be the best and provide exemplary service to all of our customers, present and new.

HXTech has a complete and scientific quality management system and has been recognized by the industry for its integrity, strength & product quality. While continuously improving the technical level and management capabilities of employees, the company adheres to the tenet of "Quality makes the brand, details determine success or failure, and integrity creates the future". With the principle of "Quality Assurance, Reasonable Price, Timely Delivery, and Service-oriented". "Creation" is our mission. "From product innovation to industrial innovation" is the mission of the times. has a complete and scientific quality management system and has been recognized by the industry for its integrity, strength & product quality. While continuously improving the technical level and management capabilities of employees, the company adheres to the tenet of "Quality makes the brand, details determine success or failure, and integrity creates the future". With the principle of "Quality Assurance, Reasonable Price, Timely Delivery, and Service-oriented". “customer business-centric model". "From product innovation to industrial innovation" is the mission of the times.

With a focus on continuous improvement, we strive to provide our customers with the best experience possible by delivering high-quality parts at competitive pricing.

Our Mission

Our mission goes beyond manufacturing quality products at a competitive price. It is our passion to build strong relationships with our customers and become a valued extension of their business. We take pride in our commitment to continuous improvement, sustainable practices, and superior customer service. We strive to prove that we are the right choice for our customer’s machining and assembly needs.

Our Vision

Our vision is to become a leading manufacturer of precision products across multiple industries while providing growth for the company, our customers, and our employees.

Our Values

Honesty – We build trust by having open and honest relationships with effective communication

Integrity – We believe in doing the right thing and holding ourselves to a higher standard of conduct

Dependability – We commit to being a vendor our customers can depend on

Ingenuity – We accept challenges and welcome the opportunity to solve problems through teamwork

Dedication – We stake our personal and professional reputations on the excellence of our work.

After sales service

WE support 24Hours/7D afer sales service online.

High levels of Customer Service and Customer Satisfaction are our TOP priorities.

We promise we can make you happy if you give us a fair chance.

If you are happy with the product, we would really appreciate if you left a positive feedback.

If you have any issues or are unhappy with the item for any reason.

Please do not hesitate to contact us first before leaving any negative feedback.

We will do our most to resolve this situation.

FAQ

Q1、Are you a manufacturer? Do you have a factory?

A1:We are a professional manufacturer for more than 15 years and we have factories. You can follow our google map address.

Q2、Can I get samples for free? Is it possible to ship for free?

A2:In view of account the uniqueness and confidentiality of customized non-standard Mould, after confirming all the detailed information, it is necessary to charge you for samples and you need to bear the corresponding shipping costs. If you subsequently purchase a large number of products, we will follow your order as much as possible with some discounts and exemption of sample fees.

Q3、Do you able to make OEM?

A3:Yes, it is. We have laser machines that can mark your logo and size. We can also design stickers with your logo.

Q4、How about your delivery time?

A4:Depending on the size and quantity and complexity of the process, the delivery time is usually within 5-15 days. When we know the detailed product acceptance criteria and technical requirements details, we can tell you the exact delivery time.

The following technical requirements shall be provided before purchasing project details:

Part information (2D/3D drawings, material, critical dimension tolerance, weight, purpose, etc.)

Special materials (purchase channels, designated suppliers)

Designated process (subdivision process is best)

What equipment is needed?

Monthly/annual usage/estimated usage

Project intent/purpose

Project development cycle

Requirements for suppliers (certification, scale)

Whether it is an urgent item (lead time xxxx days)

Focus on the points of concern (price/quality)

Difficulties of the product

Complicated problems with existing products

Are there requirements for the product life cycle?

Quality inspection requirements (testing equipment)

Testing requirements

Target price

payment terms

Shipment date

Brass Casting Mold

Brass Casting Mold Kalup za lijevanje aluminija

Kalup za lijevanje aluminija Kalup za lijevanje magnezija

Kalup za lijevanje magnezija Kalup za lijevanje cinkom

Kalup za lijevanje cinkom Kalup za lijevanje od legure

Kalup za lijevanje od legure Uložite kalup za lijevanje

Uložite kalup za lijevanje